Just How Membrane Layer Switches Add To the Sturdiness of Electronic Control Panels

Membrane buttons play a critical duty in improving the toughness of digital control panels, primarily with their multi-layered building which provides effective defense against environmental factors such as dampness and dust. The lack of moving parts considerably minimizes the chance of mechanical failings, making membrane layer changes ideal for demanding applications.

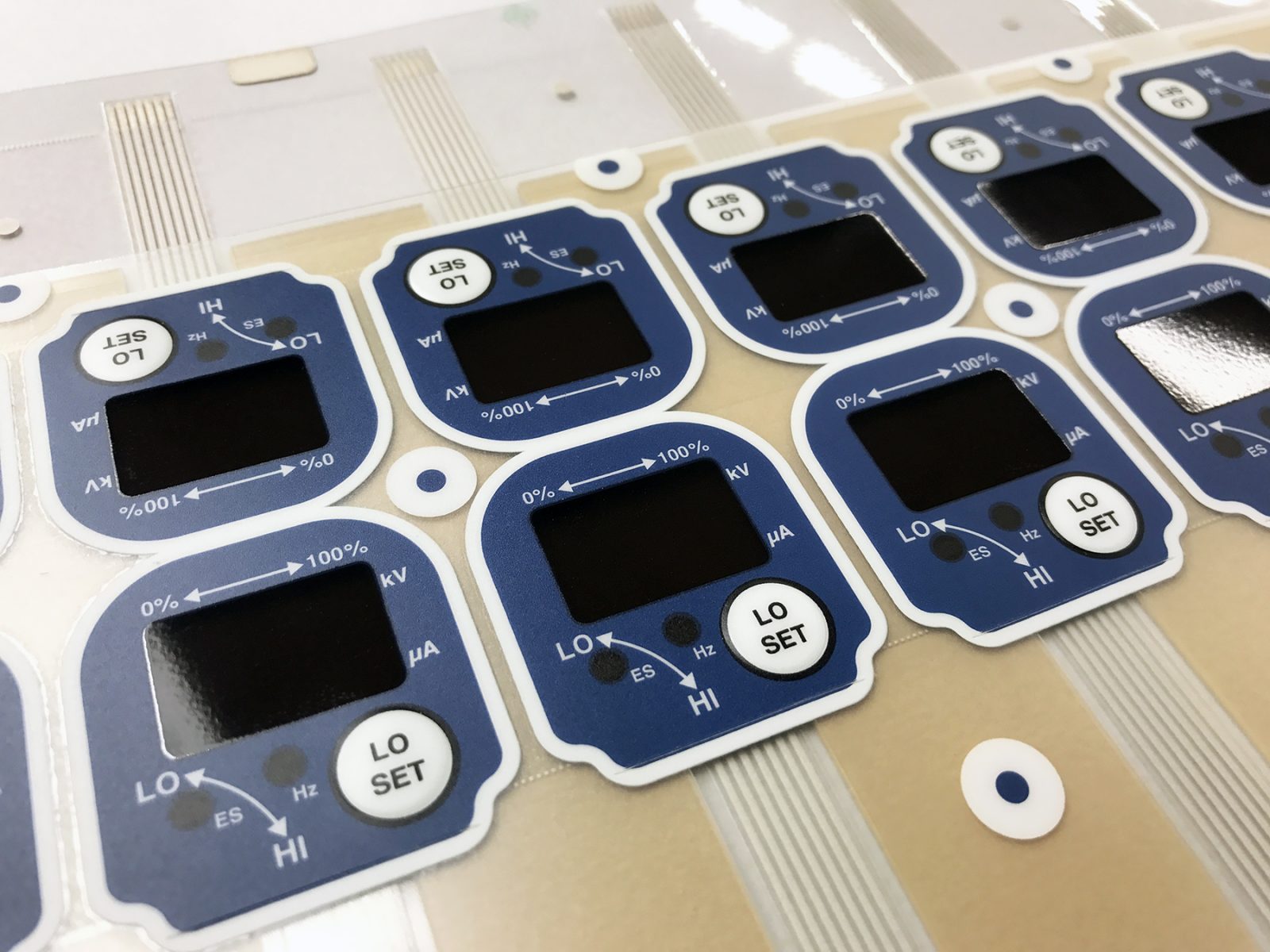

Meaning of Membrane Buttons

Membrane layer buttons are developed to be thin and lightweight, making them ideal for applications where room is limited. They can be produced in numerous forms, sizes, and shades, supplying versatility in design that satisfies visual and useful needs. Additionally, membrane layer buttons can integrate different technologies, such as responsive feedback and LED indicators, enhancing individual experience.

Because of their building and construction, membrane switches are commonly resistant to dirt, dampness, and basic wear, adding to their resilience in demanding atmospheres. Their seamless layout not just promotes easy cleaning however additionally minimizes the danger of mechanical failure, making them a preferred selection for producers seeking dependable individual interfaces in their electronic control board.

Protection Against Ecological Variables

The design of membrane switches over inherently gives a degree of protection versus numerous ecological elements, which is crucial for keeping performance in difficult problems - Membrane Switch. These switches are typically constructed with layers of adaptable materials that protect interior components from dampness, dirt, and contaminants. By enveloping the circuitry, membrane switches over decrease the danger of brief circuits and rust, which can considerably harm performance

Furthermore, using durable adhesives and sealants during manufacturing enhances their resistance to environmental obstacles. Membrane layer switches can sustain exposure to chemicals and solvents, making them appropriate for sectors such as food processing and medical care, where health and sanitation are paramount. Their smooth surface layout also protects against the build-up of dirt and germs, facilitating less complicated cleaning and upkeep.

Temperature variations are one more ecological worry, and membrane buttons are crafted to operate effectively throughout a vast range of temperatures (Membrane Switch). This flexibility makes certain that control panels stay operational in various settings, from commercial settings to customer electronic devices

Impact on User Communication

User communication with electronic control board is significantly influenced by the layout and capability of membrane switches. These switches give a tactile interface that boosts the total individual experience, allowing for intuitive navigating and control. Their responsive nature ensures that individuals get instant responses upon activation, which is vital for jobs requiring accuracy and effectiveness.

Furthermore, the smooth surface area of membrane switches facilitates very easy cleaning and maintenance, promoting customer self-confidence in the dependability of the user interface. This cleanliness is especially crucial in settings where hygiene is extremely important, such as medical or food handling settings. Additionally, the small and lightweight design of membrane switches contributes to the aesthetic charm of control panels, motivating user involvement through a modern-day and smooth appearance.

Additionally, the integration of visual components, such as published icons and backlighting, assists customers swiftly identify features, reducing the learning curve connected with new devices. Because of this, customers can run devices more efficiently, resulting in enhanced performance and satisfaction. In recap, membrane layer switches play a crucial role in improving user communication by incorporating capability, aesthetic appeals, and ease of usage, inevitably bring about improved functional effectiveness.

Style Flexibility and Personalization

Design adaptability and personalization are important elements of membrane buttons, making it possible for makers to tailor electronic control panels to details applications and user needs. This adaptability enables the integration of various design components, such as colors, graphics, and textures, which can improve the aesthetic appeal and learn this here now individual engagement of the control panel.

Membrane layer buttons can be customized in size and form, suiting a large range of gadgets and applications, from industrial equipment to consumer electronics. This flexibility makes certain that producers can create intuitive interfaces that straighten with individual assumptions and functional demands. In addition, the capability to integrate special features such as backlighting or tactile responses better boosts usability, enabling a much more interactive experience.

Furthermore, the production procedure for membrane changes supports the fast prototyping of designs, making it possible for manufacturers to iterate and fine-tune their principles promptly. This capability not just increases the development timeline but likewise makes certain that the last item meets certain functional and aesthetic criteria.

Cost-Effectiveness and Long Life

Cost-effectiveness and durability are significant benefits of membrane switches, making them an attractive option for makers and end-users alike. These buttons are normally more economical to produce than typical mechanical buttons, mostly as a result of their streamlined manufacturing procedures and the minimized number of elements needed. This expense benefit extends not only to first manufacturing but additionally to long-term operational expenditures, as membrane buttons commonly call for much less upkeep and have a reduced failing price.

In addition, the long life of membrane layer changes contributes to their general value. Created from long lasting products, they are resistant to ecological factors such as dampness, dirt, and chemicals, which can lead to premature wear in various other button kinds. The lack of moving parts lessens mechanical failing, allowing membrane layer changes to keep capability over prolonged durations.

This sturdiness is specifically valuable in applications requiring constant performance under demanding conditions, such as clinical gadgets and industrial equipment. Eventually, the mix of cost-effectiveness and durability makes membrane changes an economically feasible choice for look at this website makers, giving reliable solutions that endure the test of time while maximizing monetary factors to consider.

Verdict

In verdict, membrane buttons dramatically boost the resilience of look at here digital control board through their durable construction and protective features. By effectively shielding wiring from environmental risks and lessening the threat of mechanical failure, these buttons ensure consistent efficiency in requiring applications. The seamless design promotes health and simplicity of maintenance, while customization options allow customized remedies for various demands. In general, membrane layer changes stand for a reputable and cost-effective selection for boosting the long life and capability of electronic control systems.